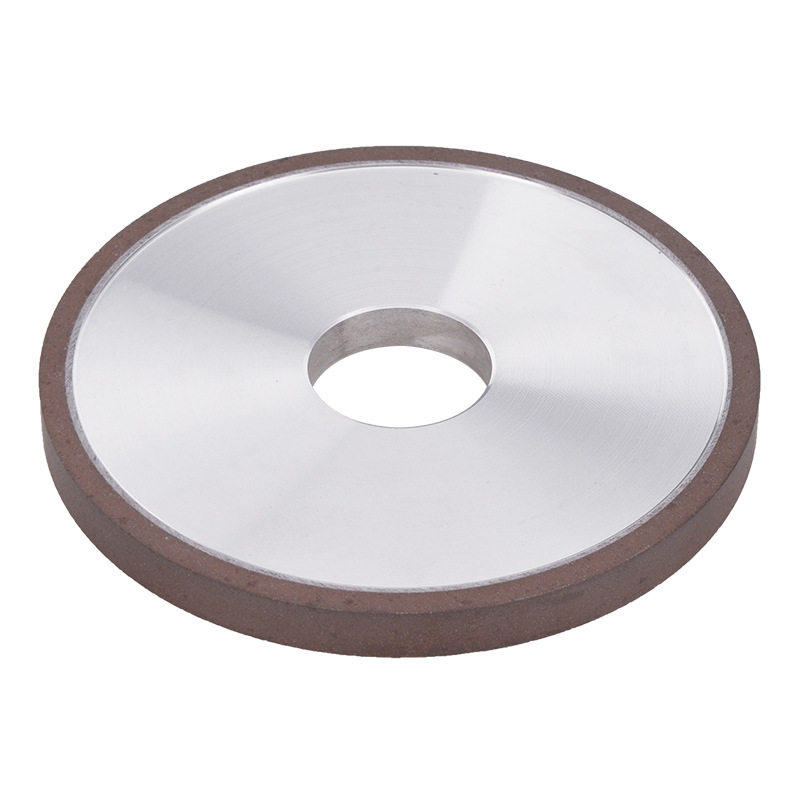

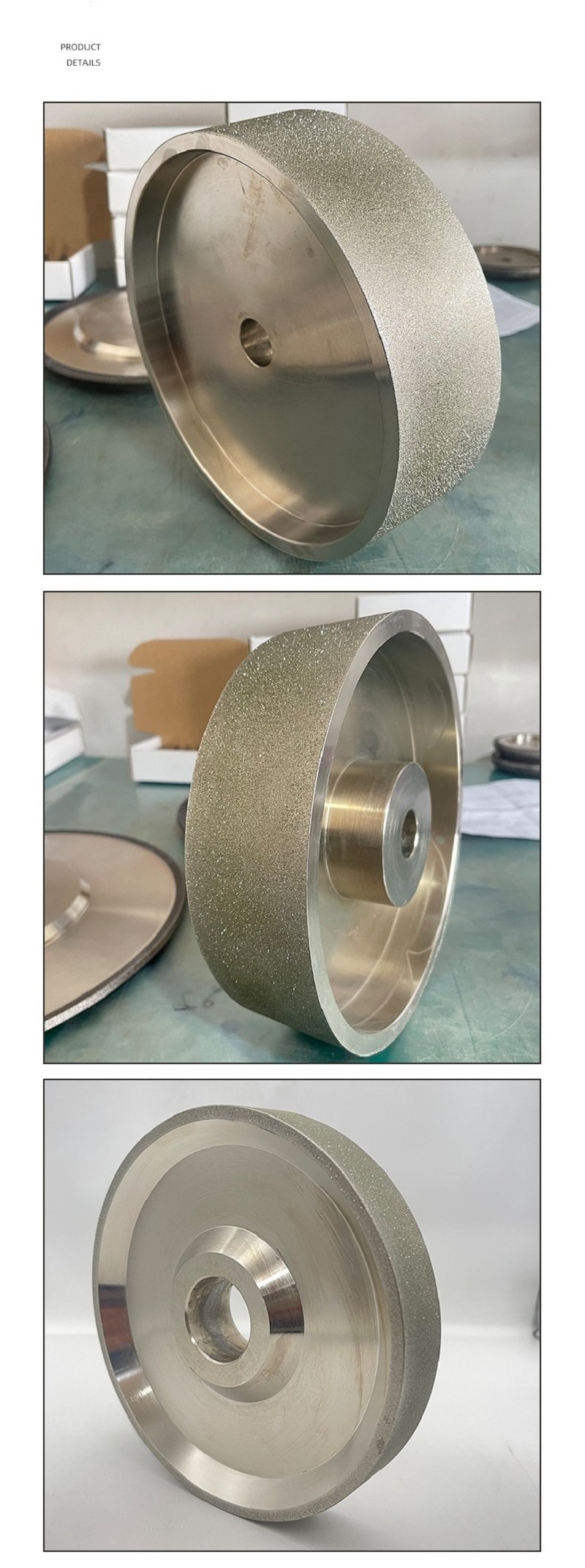

Electroplated Diamond Grinding Wheel for glass

Features

1. The grinding wheel is coated with a layer of diamond abrasive grains, which provides high hardness and wear resistance and can grind glass efficiently.

2. The diamond particles are firmly bonded to the surface of the grinding wheel through the electroplating process to ensure firm and uniform abrasive distribution.

3. Electroplated diamond grinding wheels can perform precise and fine grinding of glass, suitable for applications requiring high precision and smooth surface finish.

4. Electroplated diamond grinding wheels produce a clean and polished surface on glass surfaces, minimizing chipping and micro-cracks for high-quality results.

PRODUCT show

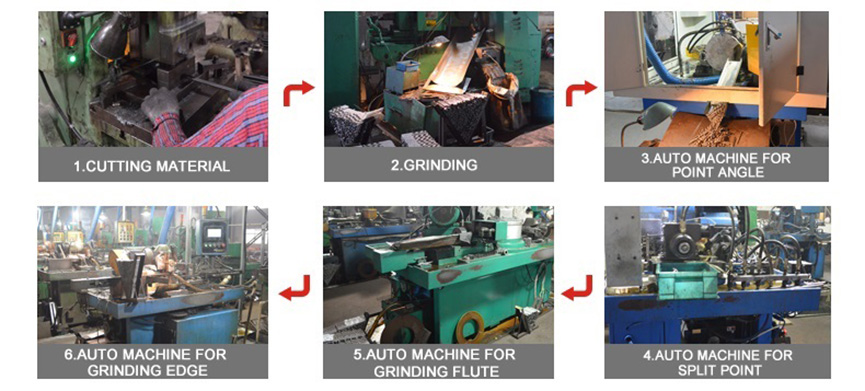

PROCESS FLOW

Advantages

1. HSS twist drill bits are made of high-speed steel, which is a type of tool steel known for its excellent hardness, durability, and heat resistance. This allows the drill bits to withstand high temperatures generated during drilling, reducing the risk of tool failure and prolonging their lifespan.

2. HSS twist drill bits can be used to drill holes in a wide range of materials, including metal, wood, plastic, and composite materials. This versatility makes them suitable for various industries and applications.

3. HSS twist drill bits have sharp cutting edges that efficiently cut into the material being drilled. The high-speed steel material allows for faster drill bit rotation, resulting in improved cutting performance and reduced drilling time.

4. HSS twist drill bits are designed to provide accurate and precise drilling, producing clean and smooth holes. This is particularly important when drilling holes for specific fasteners or components that require precise measurements.

5. Wide Range of Sizes: DIN338 jobber length HSS twist drill bits are available in various sizes to accommodate different hole diameters. This allows for flexibility in drilling operations and provides options for specific hole sizes and requirements.

6. HSS twist drill bits are generally more affordable compared to other specialized drill bits, making them a cost-effective choice for general drilling applications. They offer a good balance between performance and price, making them widely accessible and economical.

7. HSS twist drill bits are user-friendly and can be easily operated with standard drilling equipment. They have a cylindrical shank design that fits into standard drill chucks, ensuring easy installation and secure tool clamping.

8. HSS twist drill bits can be resharpened when they become dull or worn out. This feature allows users to extend the lifespan of the drill bits, making them more cost-effective in the long run.