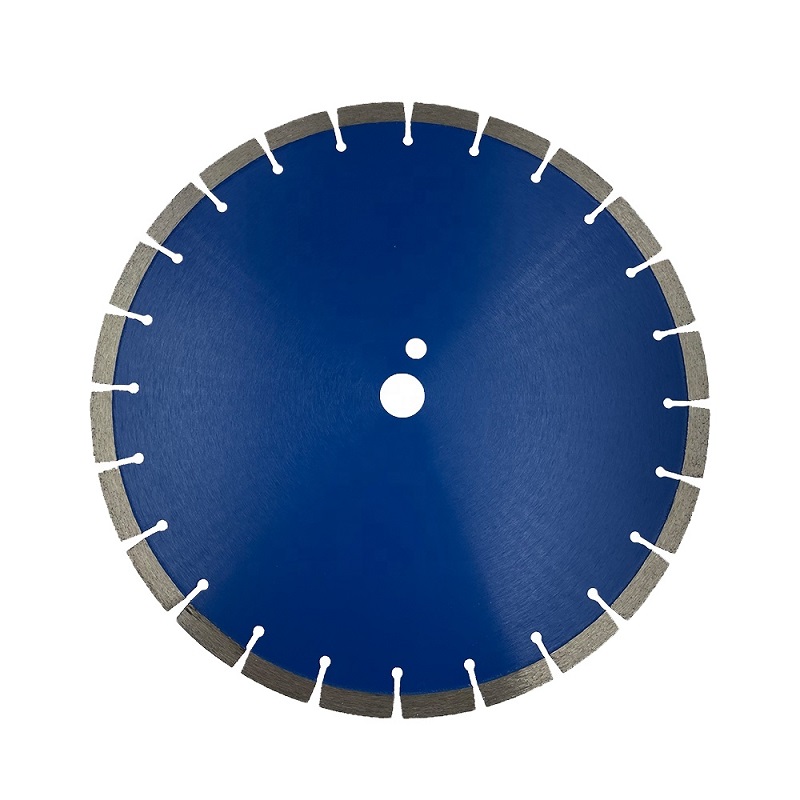

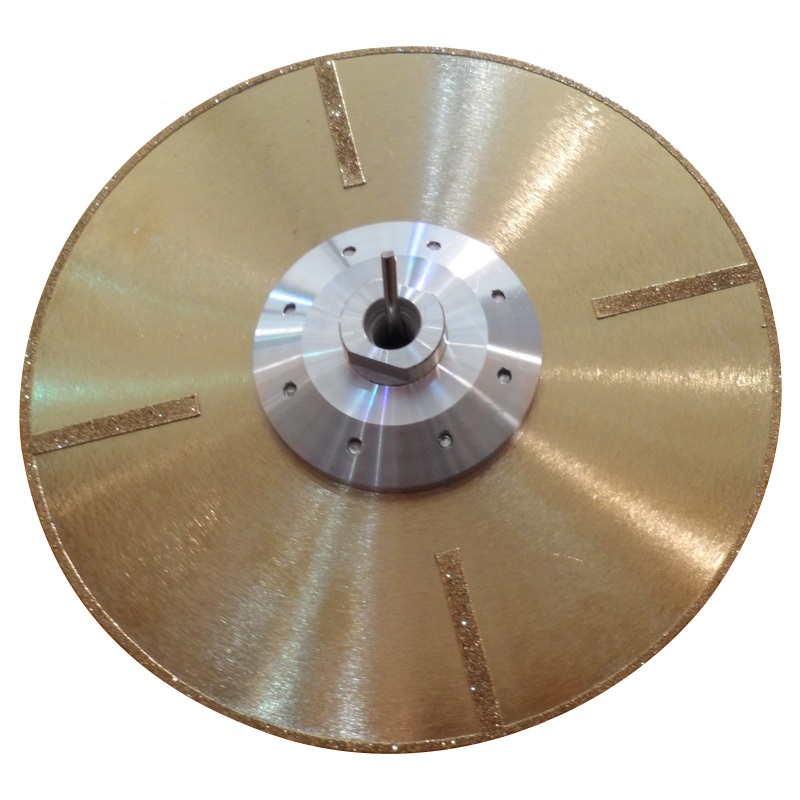

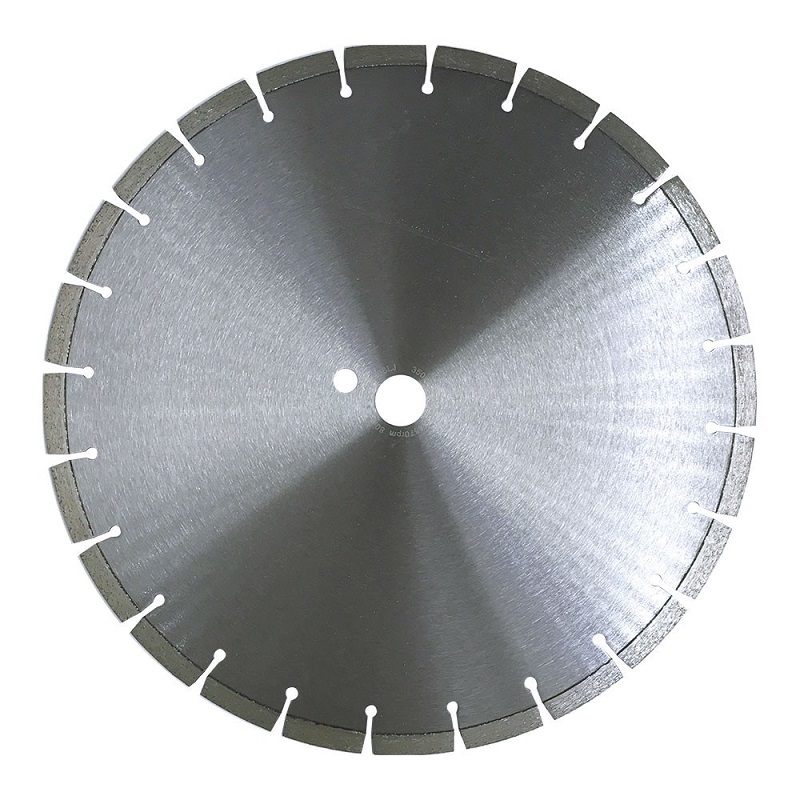

High quality brazed Diamond Saw Blade for Asphalt Stone

Features

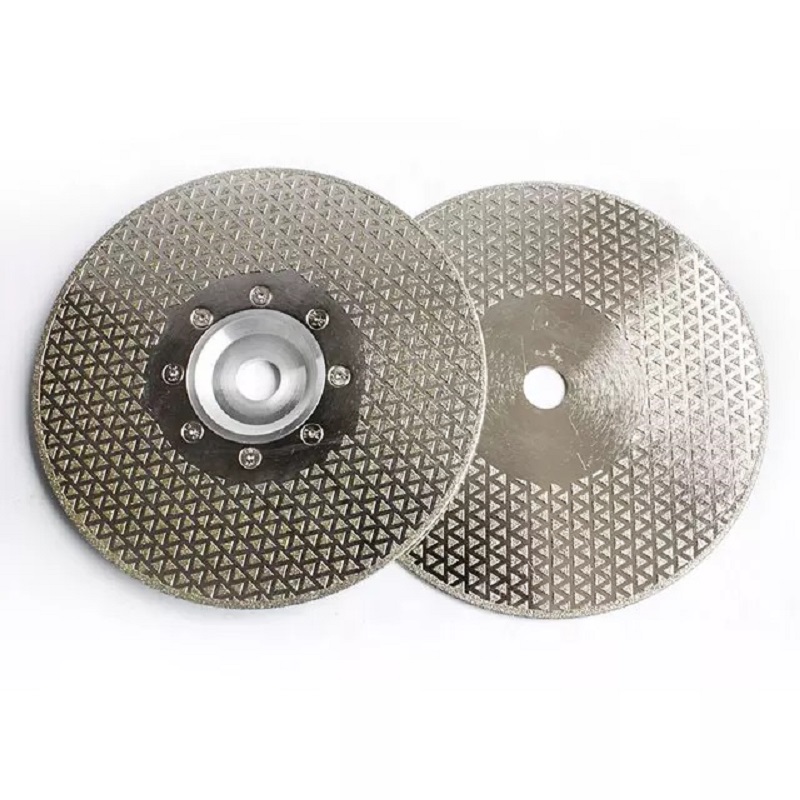

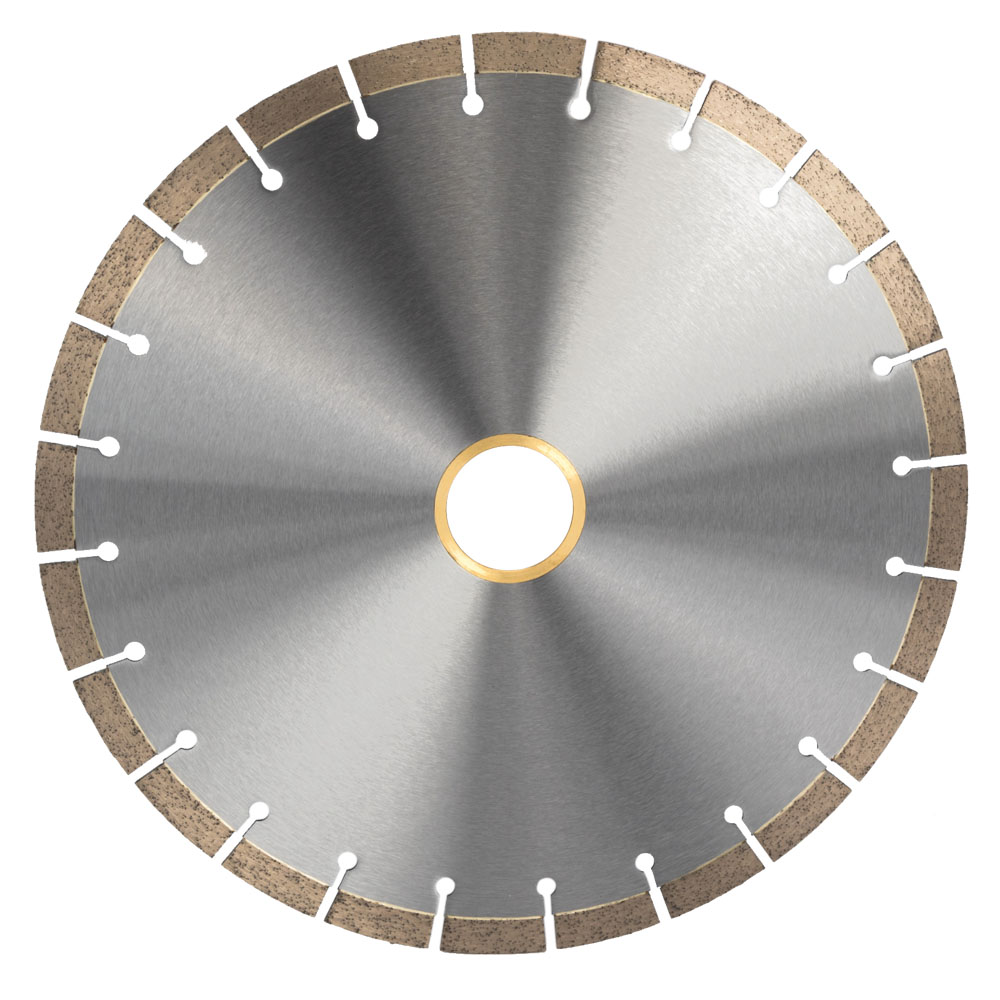

1. High-Quality Diamond Grit: The brazed diamond saw blade for asphalt stone is made with high-quality diamond grit that is firmly bonded to the saw blade using a brazing technique. This ensures excellent cutting performance and long-lasting durability.

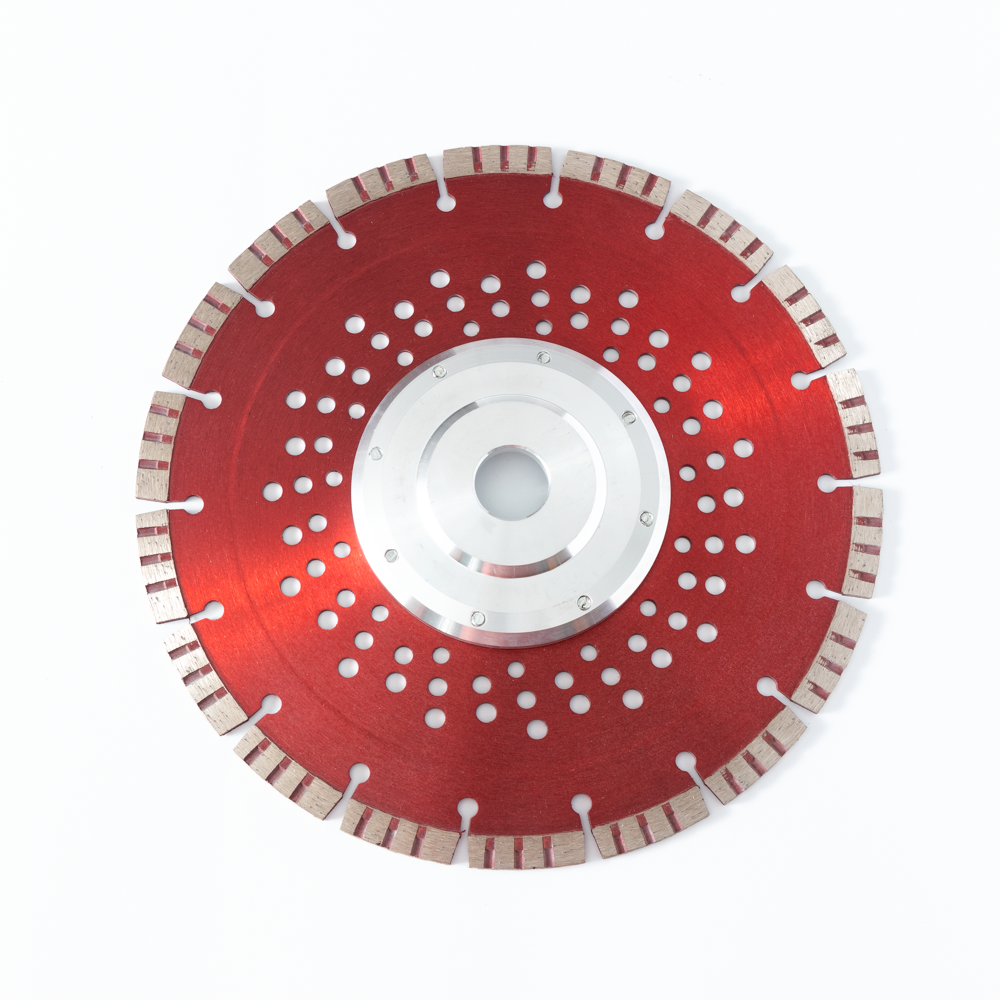

2. Fast and Efficient Cutting: The diamond grit on the saw blade is specifically designed for cutting through asphalt stone quickly and efficiently. It provides aggressive cutting action, allowing for fast and precise cuts.

3. Heat Resistance: The brazing technique used to bond the diamond grit to the saw blade ensures high heat resistance. This is important when cutting through asphalt stone, as it generates heat during the cutting process. The saw blade can withstand the heat and continue to deliver optimal cutting performance without losing its sharpness.

4. Smooth Cutting Surface: The brazed diamond saw blade provides a clean and smooth cutting surface on the asphalt stone. This feature is essential for achieving a professional finish in asphalt cutting applications.

5. Long Lifespan: Due to the strong bond between the diamond grit and the blade, the brazed diamond saw blade has a longer lifespan compared to other types of blades. It can withstand the abrasive nature of asphalt stone and maintain its cutting efficiency for an extended period.

6. Versatility: While specifically designed for cutting asphalt stone, the brazed diamond saw blade can also be used for cutting other materials such as concrete and masonry. This versatility makes it a valuable tool in various construction and renovation projects.

7. Easy to Use: The brazed diamond saw blade is easy to attach to the cutting tool, such as a circular saw or angle grinder, making it convenient for both professionals and DIY enthusiasts.

8. Reduces Chipping: The design of the brazed diamond saw blade helps reduce chipping during the cutting process. This feature ensures cleaner cuts and reduces the need for additional finish work.

9. Compatible with Wet and Dry Cutting: The brazed diamond saw blade can be used for both wet and dry cutting applications in asphalt stone. It allows for flexibility in different working conditions and can adapt to the user's preferences.

10. Cost-Effective: Despite its high-performance features, the brazed diamond saw blade offers a cost-effective solution for cutting asphalt stone. Its long lifespan and efficient cutting performance contribute to reducing replacement costs, making it a cost-efficient choice for contractors and DIYers.

Product Testing

production site

PRODUCTION PROCESS

package

| Outer diameter | Bore diameter(mm) |

Segment thickness(mm) |

Segment height(mm) |

|

| mm | inch | |||

| 105 | 4 | 22.23 | 2.0 | 8/10 |

| 115 | 4.5 | 22.23 | 2.0 | 8/10 |

| 125 | 5 | 22.23 | 2.2 | 8/10 |

| 150 | 6 | 22.23 | 2.4 | 8/10 |

| 180 | 7 | 22.23 | 2.4 | 8/10 |

| 200 | 8 | 22.23 | 2.4 | 8/10 |

| 230 | 9 | 22.23 | 2.6 | 8/10 |

| 250 | 10 | 22.23 | 2.8 | 8/10 |

| 300 | 12 | 25.4 | 3.0 | 8/10/12 |

| 350 | 14 | 25.4 | 3.2 | 8/10/12 |

| 400 | 16 | 25.4 | 3.8 | 8/10/12 |

| 450 | 18 | 50 | 4.0 | 8/10/12 |

| 500 | 20 | 50 | 4.2 | 8/10/12 |

| 550 | 22 | 50 | 4.6 | 8/10/12 |

| 600 | 24 | 50 | 4.6 | 8/10/12 |