High quality Tin-Coated HSS Hole Saw

Advantages

1. The tin coating adds an extra layer of protection to the HSS material, making it more resistant to wear and extending the lifespan of the hole saw. This allows for prolonged use and reduces the need for frequent replacement.

2. The tin coating provides better heat resistance during drilling operations. This is especially beneficial when working on materials that generate heat, such as metals. The increased heat resistance helps to prevent the hole saw from overheating and losing its cutting edge, ensuring efficient and consistent performance.

3. The tin coating acts as a lubricant, reducing friction between the hole saw and the material being cut. This results in smoother cutting and less resistance, making it easier to feed the saw through the workpiece. Reduced friction also minimizes the chances of the hole saw getting stuck or jammed during operation.

4. The sharpness of the HSS teeth, combined with the reduced friction provided by the tin coating, results in clean and precise cuts. This is especially important for applications where the accuracy and quality of the holes are crucial, such as in carpentry or electrical work. The clean cuts also reduce the need for additional finishing or post-processing work.

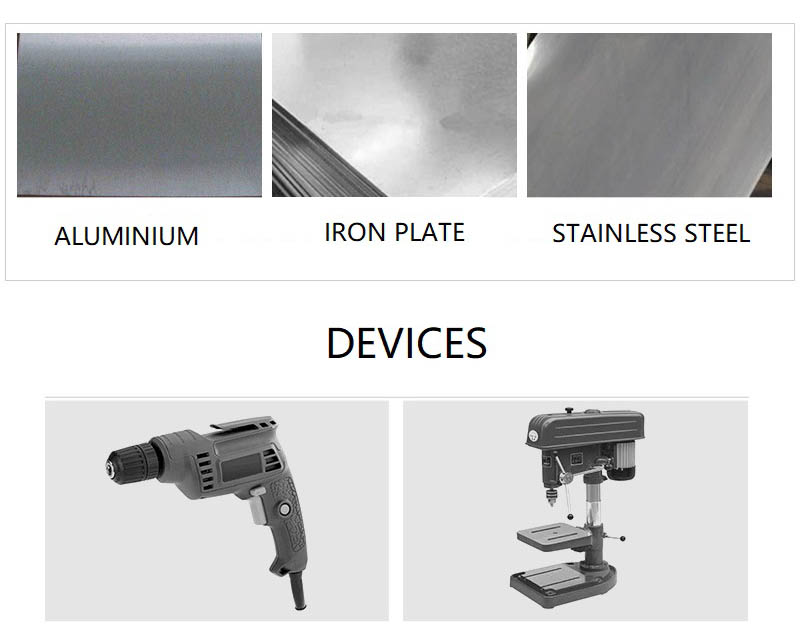

5. HSS hole saws with a tin coating are suitable for cutting a wide range of materials, including wood, plastic, and various metals. This versatility makes them a valuable tool for professionals or DIY enthusiasts who work with different materials and need a reliable cutting solution.

6. The tin coating helps to prevent the accumulation of debris and reduces the risk of rust or corrosion. This makes the hole saws easier to clean and maintain, ensuring that they remain in optimal condition over time.

7. High-quality tin-coated HSS hole saws are designed to be compatible with standard arbors or mandrels used in drilling machines. This ensures easy installation and smooth operation with most commonly available tools.

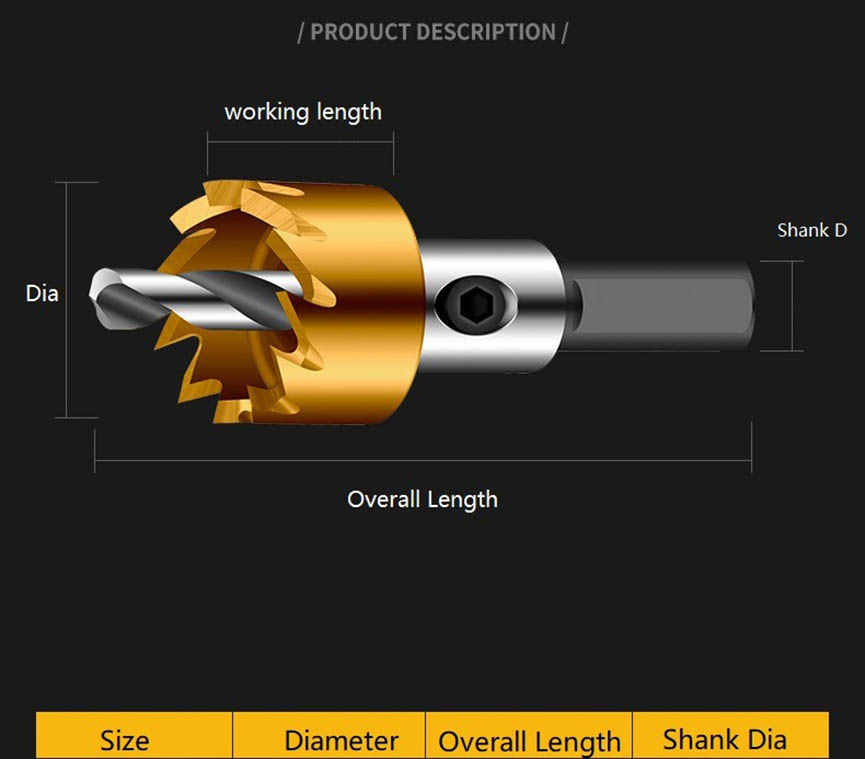

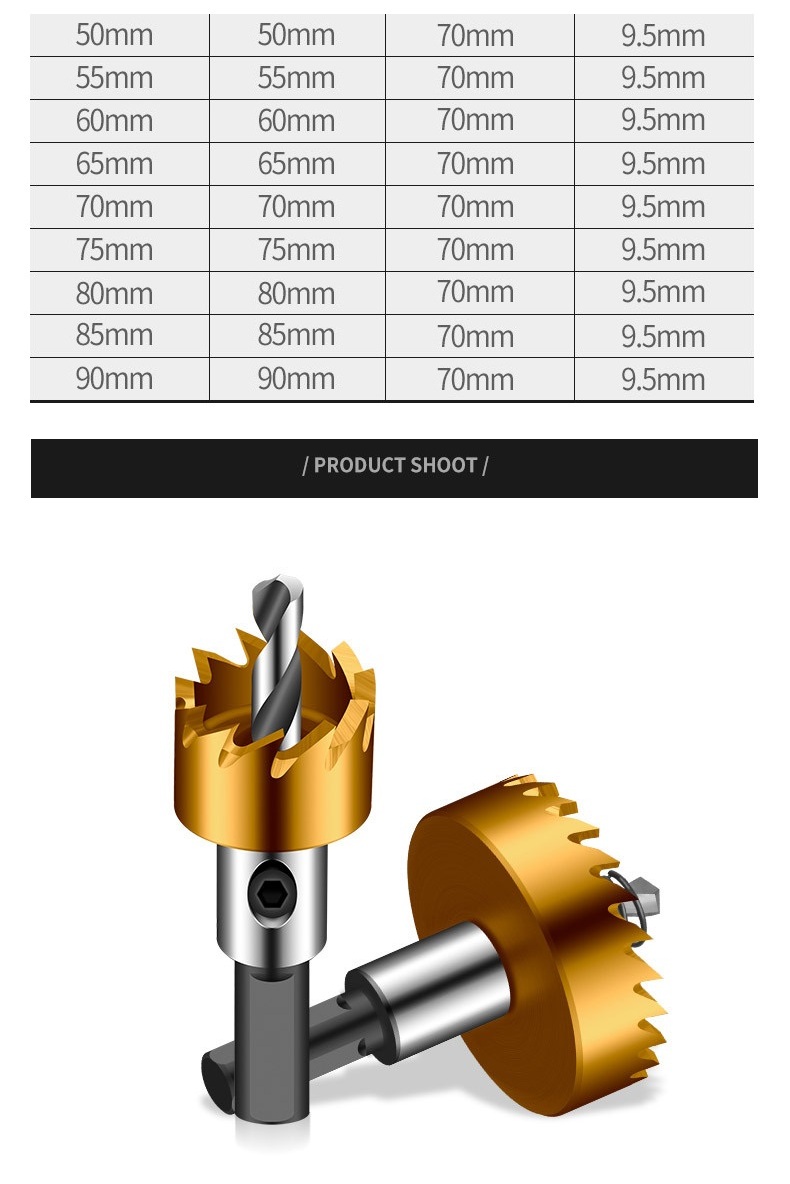

Product Detail