M10 Vacuum Brazed Diamond Core Drill Bits for Stone

Features

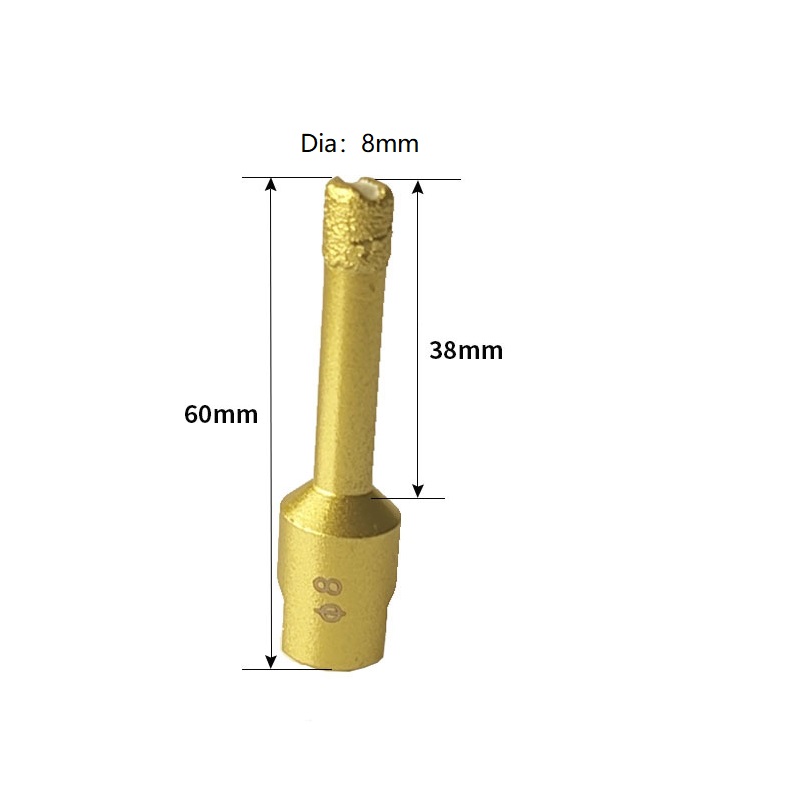

1. These core drill bits are manufactured using vacuum brazing technology. This process involves bonding diamond particles directly to the drill bit's metal body through high temperatures and vacuum conditions. This ensures a strong bond between the diamonds and the metal, resulting in enhanced durability and extended tool life.

2. The drill bits are embedded with high-quality diamond grit. The diamond particles are evenly distributed across the surface, providing excellent cutting performance and efficient material removal. The diamond grit is specifically designed for cutting through hard stone materials like granite, marble, and quartz.

3. M10 Vacuum Brazed Diamond Core Drill Bits are known for their fast and precise drilling capabilities. The diamond grit and vacuum brazing technology enable these drill bits to quickly penetrate through the stone while maintaining accuracy and precision.

4. These core drill bits are widely used in the stone industry for various applications, including drilling faucet holes, sink cutouts, anchor holes, and other detailed work. They are suitable for use on different types of stone, such as granite, marble, engineered stone, and more.

5. The vacuum brazing design enhances heat dissipation during drilling. This reduces the risk of overheating, which is crucial for extending the life of the drill bit and preventing damage to the stone material.

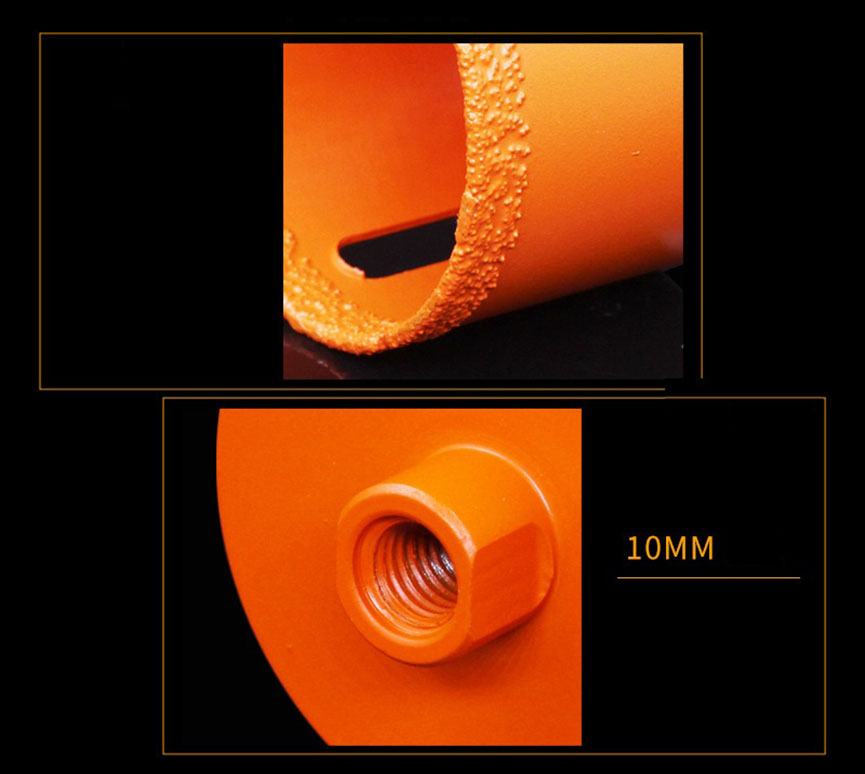

6. M10 Vacuum Brazed Diamond Core Drill Bits have an M10 connection thread, allowing for easy installation onto drilling machines or handheld drills equipped with an M10 connection. This ensures compatibility with a wide range of drilling equipment.

7. Thanks to the vacuum brazing technology and high-quality diamond grit, these drill bits have a longer lifespan compared to conventional core drill bits. This longevity translates to cost savings over time by reducing the frequency of tool replacements.

8. The vacuum brazed diamond particles provide exceptional strength and resilience to the drill bits, minimizing the risk of chipping or breakage during drilling. This ensures a smooth drilling operation and prevents damage to the stone being drilled.

M10 vacuum brazed diamond core drill bit details