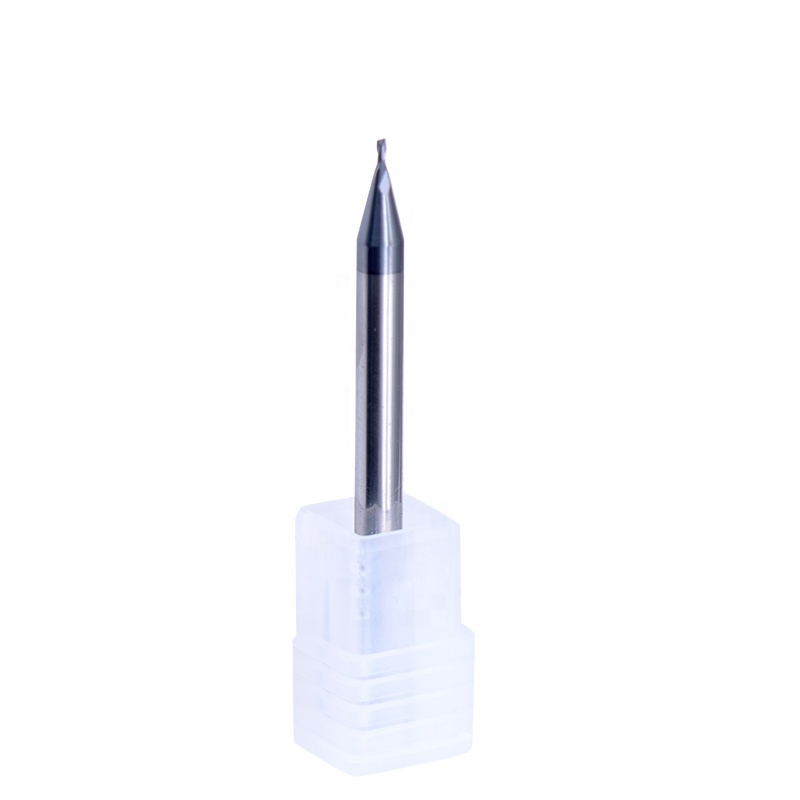

Micro Tungsten Carbide Square End Mill

Features

1. Small diameter: Micro end mills typically have a diameter ranging from 0.1mm to 6mm, allowing for precise and intricate cuts in tight spaces. This enables the machining of fine details and small features with high accuracy.

2. High hardness: Tungsten carbide is known for its excellent hardness, which ensures the micro end mill's durability and resistance to wear. This makes them suitable for machining hard materials like stainless steel, hardened tool steels, and aerospace alloys.

3. Sharp cutting edges: Micro end mills are designed with sharp cutting edges to ensure clean cuts and reduce the risk of workpiece damage or burrs. This is crucial for applications that require high surface finish and dimensional accuracy.

4. Efficient chip evacuation: The flute design of micro end mills is optimized for efficient chip evacuation, preventing chip buildup and ensuring smooth cutting operations. Proper chip evacuation helps to maintain good tool performance and reduce the chance of tool breakage.

5. Reduced cutting forces: Micro end mills are designed to minimize cutting forces, which is especially important when working with delicate or thin materials. Lower cutting forces help to prevent workpiece deflection and minimize the chance of tool wear or breakage.

6. Coating options: Micro tungsten carbide end mills can be available with various coatings, such as TiAlN, TiSiN, or diamond-like carbon (DLC). Coatings increase the tool's performance by reducing friction, improving wear resistance, and enhancing heat dissipation.

7. Multiple flute options: Micro end mills can have 2, 3, or even 4 flutes. The number of flutes affects the chip evacuation and the stability of the tool during cutting. Choosing the appropriate flute design depends on the specific application and material being machined.

8. Shank options: Micro end mills can be provided with different shank types, including straight shanks and tapered shanks. The choice of shank type depends on the machine's tool holder and the specific requirements of the machining setup.

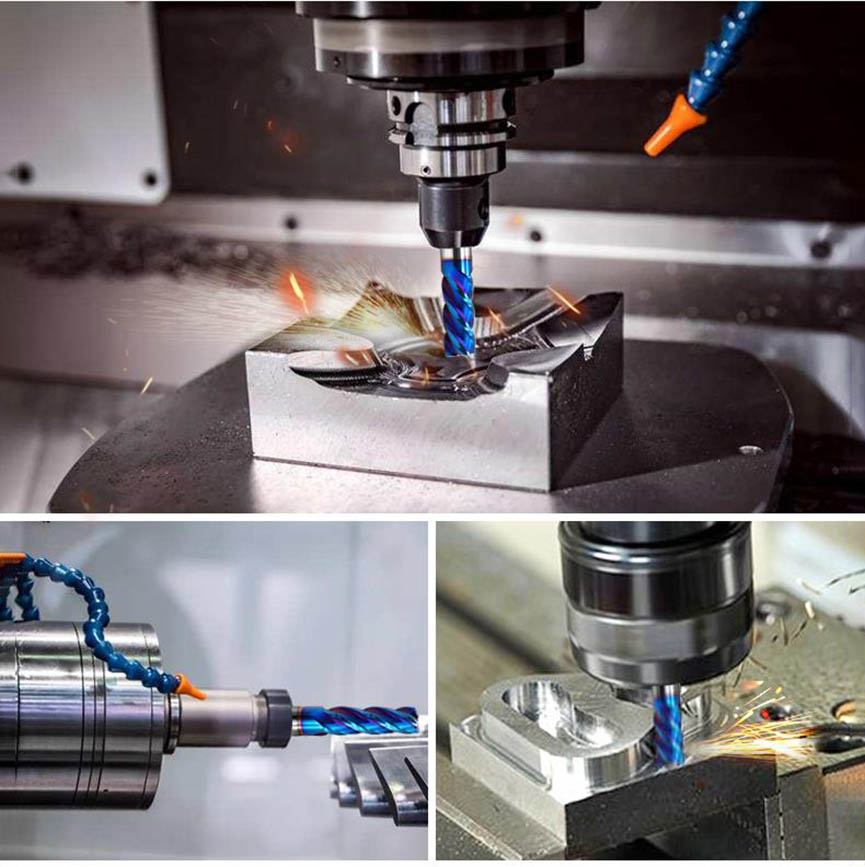

9. Application versatility: Micro tungsten carbide end mills are suitable for a wide range of applications, including micro machining, engraving, contouring, and drilling. They can be used in industries such as electronics, medical, aerospace, and precision engineering.

10. Customization options: Manufacturers often offer customization services for micro end mills, allowing customers to specify the diameter, flute length, overall length, coating, and other parameters to meet their specific machining needs.

preminium quality tungsten carbide square end mill detail

factory

| 2 Flutes Micro End Mill | ||||

| Item | Flute Diameter(d) | Flute Length(I) | Shank Diameter(D) | Overall Length(L) |

| 0.2*0.4*4*50 | 0.2 | 0.4 | 4 | 50 |

| 0.3*0.6*4*50 | 0.3 | 0.6 | 4 | 50 |

| 0.4*0.8*4*50 | 0.4 | 0.8 | 4 | 50 |

| 0.5*1*4*50 | 0.5 | 1 | 4 | 50 |

| 0.6*1.2*4*50 | 0.6 | 1.2 | 4 | 50 |

| 0.7*1.4*4*50 | 0.7 | 1.4 | 4 | 50 |

| 0.8*1.6*4*50 | 0.8 | 1.6 | 4 | 50 |

| 0.9*1.8*4*50 | 0.9 | 1.8 | 4 | 50 |