Morse Taper Shank HSS End Mills

Features

1. Morse Taper Shank: The end mill has a shank that is designed to fit into a Morse Taper spindle. The Morse Taper system allows for secure and accurate mounting of the end mill in the milling machine.

2. High-Speed Steel (HSS): HSS is a type of tool steel commonly used in cutting tools. HSS end mills are known for their toughness, heat resistance, and ability to withstand high cutting speeds. HSS end mills are suitable for a wide range of materials, including carbon steel, alloy steel, stainless steel, and non-ferrous metals.

3. Flutes: The end mill will have multiple flutes along its length. Flutes are the helical or straight grooves on the surface of the end mill. Flutes help in chip evacuation and provide cutting edges for material removal. The number of flutes can vary depending on the application, with common options being 2, 4, or 6 flutes.

4. Cutting Edge Geometry: HSS end mills come in various cutting edge geometries, such as square end, ball nose, corner radius, or chamfer. Each geometry is suited for specific milling operations and desired surface finishes.

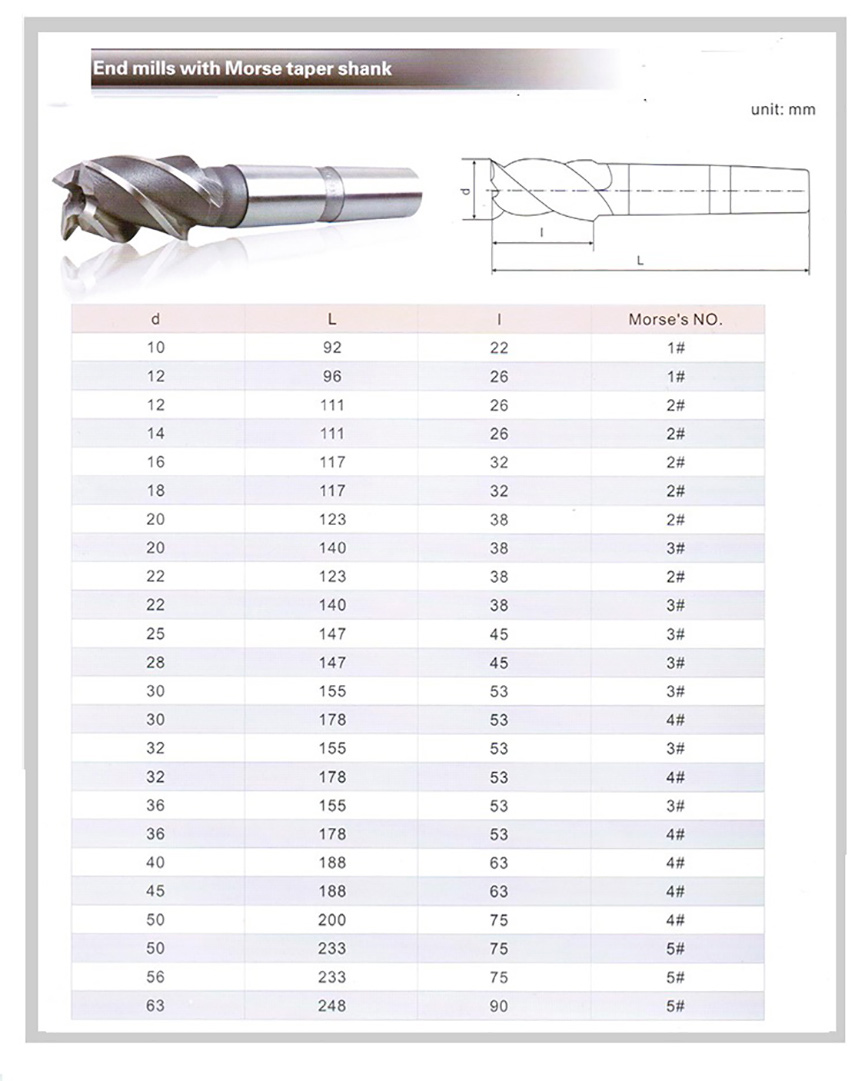

5. Overall Length and Flute Length: The overall length refers to the total length of the end mill, from the tip of the cutting edge to the end of the shank. The flute length refers to the length of the cutting portion or flutes. Different lengths are available to accommodate different milling depths and clearance requirements.

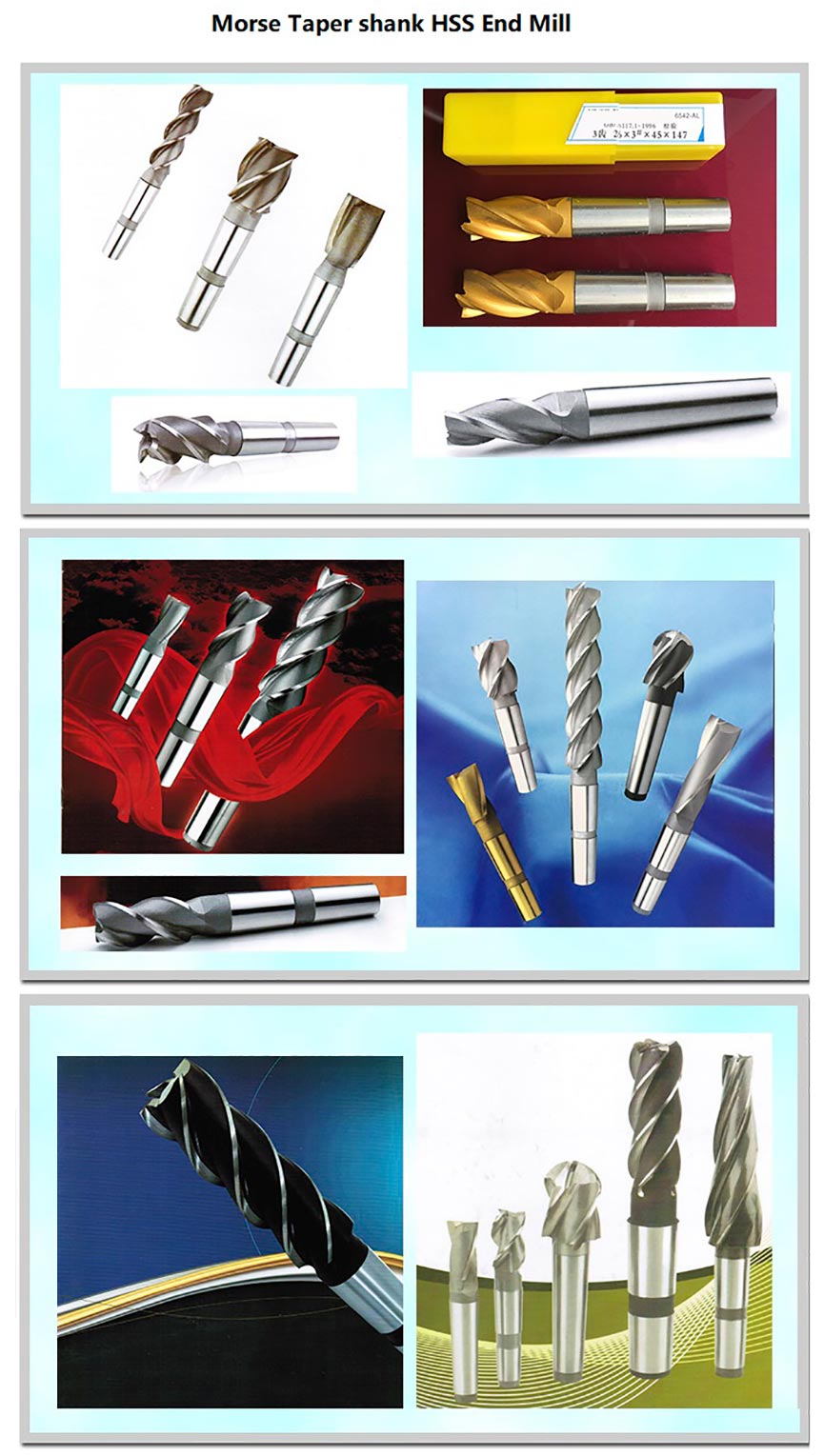

6. Coating Options: HSS end mills may also come with various coating options like TiN, TiCN, or TiAlN. These coatings provide improved wear resistance, increased tool life, and better performance in high-speed or high-temperature cutting applications.

7. Standard Sizes: Morse Taper shank HSS end mills are available in standard sizes that correspond to the Morse Taper designation (MT1, MT2, MT3, etc.). These sizes ensure proper fitting and compatibility with milling machines and spindles.

factory

Morse taper shank HSS end mill detail

Advantages

1. Secure and Accurate Mounting: The Morse Taper shank provides a secure and precise fit into the spindle, minimizing runout and ensuring accurate cutting. This helps maintain consistent dimensional accuracy and surface finish in the machined parts.

2. Versatility: Morse Taper shank HSS end mills are available in a wide range of sizes and geometries, making them suitable for various milling operations and material types. This versatility allows for a broader range of applications without the need for multiple tooling setups.

3. Durability and Heat Resistance: HSS end mills are known for their toughness and resistance to heat. They can withstand high cutting speeds and maintain their cutting performance even under intense heat generated during machining. This durability translates into longer tool life, reducing the frequency of tool replacement and downtime in the machining process.

4. Cost-Effective: HSS end mills are generally more cost-effective compared to other high-performance tool materials, such as carbide. HSS end mills offer a good balance between performance and cost, making them a suitable choice for lower volume machining, challenging materials, or applications with less stringent requirements.

5. Compatibility: Morse Taper shank HSS end mills are designed to be compatible with standard Morse Taper spindles commonly found in milling machines. This compatibility simplifies tool setup, reduces the need for additional adapters, and allows for easy interchangeability between different tools.

6. Resharpening Capability: HSS end mills can be easily resharpened, extending their useful life and reducing tooling costs over time. With proper maintenance and sharpening, an HSS end mill can deliver consistent performance and value over multiple machining cycles.

7. Wide Material Compatibility: HSS end mills can effectively machine a wide range of materials, including carbon steel, alloy steel, stainless steel, cast iron, non-ferrous metals, and plastics. This versatility makes them suitable for a variety of industries and applications.