Segments for diamond saw blade and core bits

advantages

1.These bits are typically made from various materials such as diamond, abrasive, or a combination of both. Diamond bits are known for their high cutting efficiency and durability and are suitable for cutting hard materials such as concrete, masonry and stone. Abrasive discs are typically used for cutting softer materials.

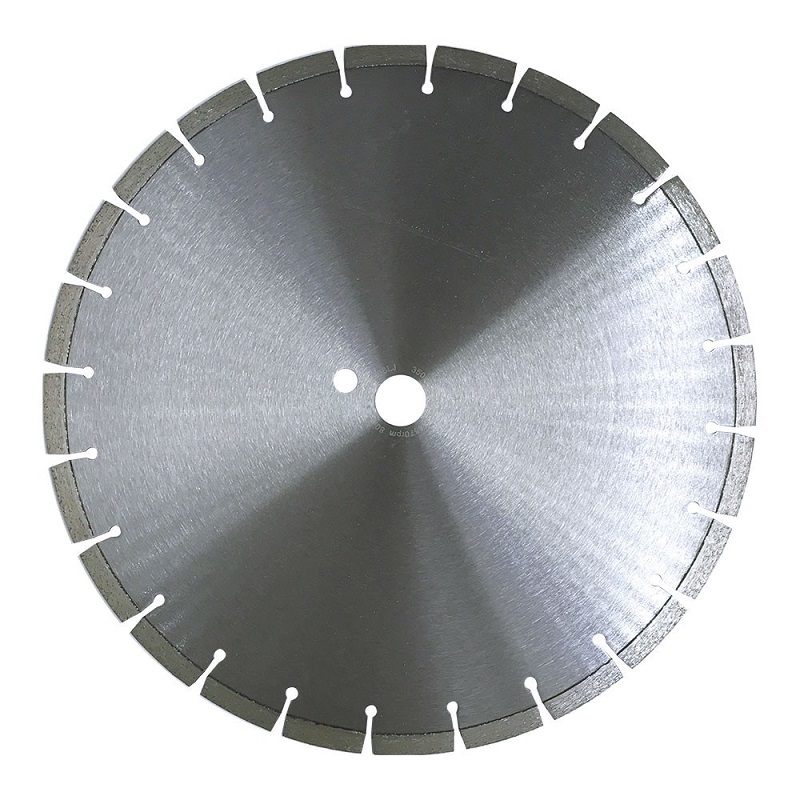

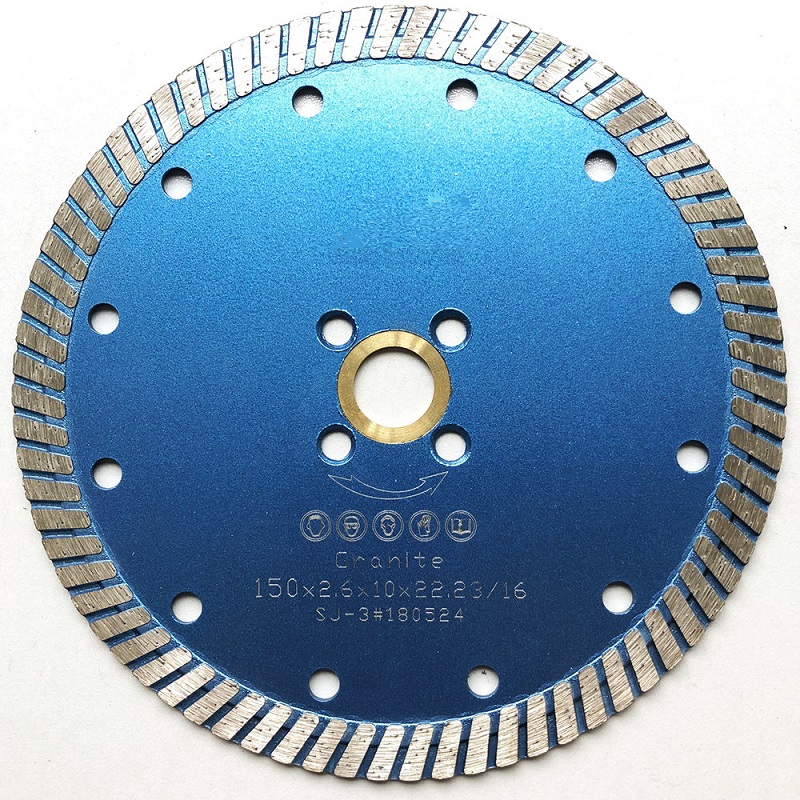

2.The shape and design of the blade play a vital role in determining cutting speed, accuracy, and the ability to dissipate heat during the cutting process. Common bit shapes include turbine, wave, segmented and continuous edge, each designed for specific cutting applications and materials.

3.The size of the cutter head, including height and thickness, directly affects the cutting depth and the stability of the cutting process. Larger heads are typically used for heavy-duty cutting, while smaller heads can be used for finer, more precise cuts.

4.The bonding process that connects the blade segment to the saw blade or coring bit affects the strength and stability of the tool. Segments can be joined using a variety of bonding methods, including sintering, laser welding or brazing, each offering specific advantages in terms of strength and heat resistance.

5.The number and arrangement of bits on a blade or coring drill affects cutting efficiency, heat dissipation and the smoothness of the cutting action. Choose from different configurations, such as segmented, continuous or turbine, depending on your specific cutting needs and materials being processed. \

6.Some bits are designed with special features, such as undercut protection, gullets for effective debris removal, or cooling holes to prevent overheating during long cutting operations.

7.The cutter head can be designed for specific cutting applications, such as concrete cutting, asphalt cutting, tile cutting or drilling in a variety of materials, ensuring optimal performance and longevity for the specific task.

Product Testing

FACTORY SITE

| Product Name | Saw blade Diameter(mm) | Segment Dimension(mm) | Segment Number(pcs) | Shape |

| Diamond Segment for stone | 300 | 40×3.2×10(15,20) | 21 | B shape,K shape,M shape,Rectangle,Sandwich shape etc |

| 350 | 40×3.2×10(15,20) | 24 | ||

| 400 | 40×3.6×10(15,20) | 28 | ||

| 450 | 40×4.0×10(15,20) | 32 | ||

| 400 | 40×3.6×10(15,20) | 28 | ||

| 450 | 40×4.0×10(15,20) | 32 | ||

| 500 | 40×4.0×10(15,20) | 36 | ||

| 550 | 40×4.6×10(15,20) | 40 | ||

| 600 | 40×4.6×10(15,20) | 42 | ||

| 650 | 40×5.0×10(15,20) | 46 | ||

| 700 | 40×5.0×10(15,20) | 50 | ||

| 750 | 40×5.0×10(15,20) | 54 | ||

| 800 | 40×5.5×10(15,20) | 57 | ||

| 850 | 40×5.5×10(15,20) | 58 | ||

| 900 | 24×7.5×13(15) | 64 | ||

| 1000 | 24×7.5×13(15) | 70 | ||

| 1200 | 24×8.0×13(15) | 80 | ||

| 1400 | 24×8.5×13(15) | 92 | ||

| 1600 | 24×9.5×13(15) | 108 | ||

| 1800 | 24x10x13(15) | 120 | ||

| 2000 | 24x11x13(15) | 128 | ||

| 2200 | 24x11x13(15) | 132 | ||

| 2500 | 24×12.5×13(15) | 140 | ||

| 2700 | 24×12.5×13(15) | 140 |

| Diamond segment size for core drilling | ||||

| Diameter of core bit (mm) | Description | Segment size | Segment number | Welding |

| 51 | Processing materials:reinforce concrete Connection:1 1/4″ UNC; Barrel:450mm | 22*4*10 | 5 | Frequency copper welding |

| 63 | 24*4*10 | 6 | ||

| 66 | 6 | |||

| 76 | 7 | |||

| 83 | 8 | |||

| 96 | 9 | |||

| 102 | 9 | |||

| 114 | 10 | |||

| 120 | 24*4.2*10 | 11 | ||

| 127 | 11 | |||

| 132 | 11 | |||

| 152 | 24*4.5*10 | 12 | ||

| 162 | 12 | |||

| 180 | 14 | |||

| 200 | 16 | |||

| 230 | 18 | |||

| 254 | 20 | |||

| 300 | 24*5*10 | 25 | ||