Solid Carbide Square End Mills for general machining

Features

1. Material: Solid carbide square end mills are made from a single piece of carbide material, which ensures high durability and resistance to wear and tear.

2. Hardness: Carbide is known for its exceptional hardness. Solid carbide square end mills can withstand high cutting speeds and maintain their sharpness for longer periods compared to other materials.

3. Precision: Solid carbide square end mills are designed with precision in mind. They are capable of producing accurate and clean cuts, resulting in precise and high-quality workpieces.

4. Versatility: These end mills can be used in a variety of materials, including ferrous and non-ferrous metals, plastics, and composites. This versatility makes them suitable for a wide range of machining applications.

5. Efficiency: Solid carbide square end mills are designed with multiple flutes, which enhance chip evacuation and reduce the chances of clogging. This improves machining efficiency and overall productivity.

6. Heat resistance: Carbide has excellent heat resistance properties, allowing solid carbide square end mills to withstand high temperatures generated during cutting operations without losing their hardness or sharpness.

7. Longevity: Due to their high hardness and durability, solid carbide square end mills have a longer lifespan compared to other types of end mills. This results in fewer tool replacements, reducing downtime and costs.

8. High rigidity: Solid carbide end mills have high rigidity, meaning they are less likely to bend or deflect during machining operations. This rigidity leads to improved cutting stability and dimensional accuracy.

9. Coating options: Solid carbide square end mills can also be coated with various coatings such as TiN, TiCN, and TiAlN, which further enhance their performance by reducing friction, increasing tool life, and improving chip evacuation.

10. Cutting-edge geometry: Solid carbide square end mills are available in various cutting-edge geometries, such as straight, helical, and variable helix designs. These geometries offer different cutting characteristics and cater to specific machining requirements.

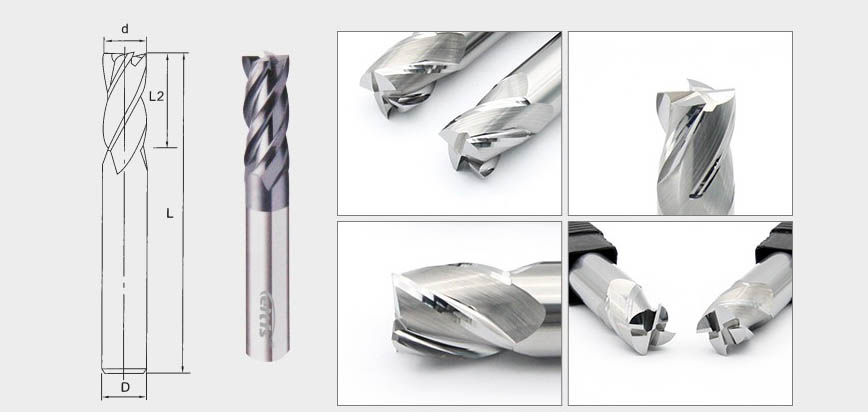

Detail display

FACTORY

Advantages

1. Durability: Solid carbide square end mills are known for their exceptional durability. Carbide material is resistant to wear and can withstand high cutting speeds and abrasive materials, resulting in longer tool life.

2. High Speed Machining: Solid carbide square end mills can efficiently perform high-speed machining operations due to their hardness and heat resistance. This allows for increased productivity and shorter machining times.

3. Excellent Chip Evacuation: The flutes on solid carbide square end mills are designed to optimize chip evacuation. This helps prevent chip build-up and ensures smooth cutting, reducing the risk of tool damage or workpiece defects.

4. Improved Surface Finish: Solid carbide square end mills produce clean and precise cuts, resulting in a superior surface finish on the workpiece. This eliminates the need for additional finishing processes, saving time and cost.

5. Versatility: Solid carbide square end mills are suitable for a wide range of materials, including metals, plastics, and composites. This versatility makes them ideal for various industries, from automotive to aerospace.

6. Enhanced Stability: Solid carbide square end mills feature high rigidity, which reduces tool deflection and enhances cutting stability. This results in improved dimensional accuracy and reduced chances of tool breakage.

7. Precision Machining: The sharp cutting edges of solid carbide square end mills allow for precise and accurate machining. This is crucial for applications that require tight tolerances and intricate detailing.

8. Heat Resistance: Solid carbide end mills can withstand high temperatures generated during machining. This heat resistance prevents the tool from softening or losing its cutting properties, ensuring consistent performance.

9. Reduced Tool Changes: Solid carbide square end mills have a longer tool life compared to other materials, reducing the need for frequent tool changes. This leads to increased production efficiency and decreased downtime.

10. Cost-Effectiveness: Although initially more expensive, solid carbide square end mills offer long-term cost savings due to their extended tool life and high-performance capabilities. This makes them a cost-effective choice for manufacturing operations.

| Blade diameter (mm) | Blade length (mm) | Full(mm) | Shank (mm) |

| 1.0 | 3 | 50 | 4 |

| 1.5 | 4 | 50 | 4 |

| 2.0 | 6 | 50 | 4 |

| 2.5 | 7 | 50 | 4 |

| 3.0 | 8 | 50 | 4 |

| 3.5 | 10 | 50 | 4 |

| 4.0 | 11 | 50 | 4 |

| 1.0 | 3 | 50 | 6 |

| 1.5 | 4 | 50 | 6 |

| 2.0 | 6 | 50 | 6 |

| 2.5 | 7 | 50 | 6 |

| 3.0 | 8 | 50 | 6 |

| 3.5 | 10 | 50 | 6 |

| 4.0 | 11 | 50 | 6 |

| 4.5 | 13 | 50 | 6 |

| 5.0 | 13 | 50 | 6 |

| 5.5 | 13 | 50 | 6 |

| 6.0 | 15 | 50 | 6 |

| 6.5 | 17 | 60 | 8 |

| 7.0 | 17 | 60 | 8 |

| 7.5 | 17 | 60 | 8 |

| 8.0 | 20 | 60 | 8 |

| 8.5 | 23 | 75 | 10 |

| 9.0 | 23 | 75 | 10 |

| 9.5 | 25 | 75 | 10 |

| 10.0 | 25 | 75 | 10 |

| 10.5 | 25 | 75 | 12 |

| 11.0 | 28 | 75 | 12 |

| 11.5 | 28 | 75 | 12 |

| 12.0 | 30 | 75 | 12 |

| 13.0 | 45 | 100 | 14 |

| 14.0 | 45 | 100 | 14 |

| 15.0 | 45 | 100 | 16 |

| 16.0 | 45 | 100 | 16 |

| 17.0 | 45 | 100 | 18 |

| 18.0 | 45 | 100 | 18 |

| 19.0 | 45 | 100 | 20 |

| 20.0 | 45 | 100 | 20 |

| 22.0 | 45 | 100 | 25 |

| 25.0 | 45 | 100 | 25 |