Staggered Segments Diamond Grinding disc

Advantages

1. Improved Surface Coverage: The staggered design of the diamond segments on the disc helps to provide better surface coverage during grinding. This ensures that the entire surface area is effectively worked on, resulting in more efficient material removal and uniform grinding.

2. Reduced Heat Build-up: The staggered layout of the diamond segments allows for improved airflow and cooling during operation. This helps to minimize heat build-up, which can be beneficial in preventing damage to the workpiece and the grinding disc itself. It also allows for longer continuous grinding without the risk of overheating.

3. Enhanced Dust and Debris Removal: The staggered segment arrangement creates channels and spaces between the diamond segments. These spaces help in the effective removal of dust, debris, and slurry generated during grinding. This promotes a cleaner working environment and reduces the risk of clogging or glazing of the diamond segments.

4. Controlled Aggressiveness: Staggered segments provide a balanced and controlled grinding action. The design allows for more precise material removal, enabling the operator to have greater control over the grinding process. This makes it suitable for tasks that require a more delicate touch or when fine-tuning and finishing surfaces.

5. Staggered segments diamond grinding discs offer versatility in grinding applications. They can be used for a wide range of materials, including concrete, stone, masonry, and even metal surfaces. This makes them suitable for various tasks, such as leveling uneven surfaces, removing thin coatings or epoxy, and achieving a polished finish.

6. The staggered segments design helps in distributing the grinding pressure evenly across the diamond segments, reducing the chances of premature wear or damage. This helps to extend the lifespan of the grinding disc, providing longer usage and cost savings.

7. The staggered segments on the diamond grinding disc allow for efficient material removal due to the increased number of cutting edges. This translates to faster and more aggressive grinding, saving time and effort on different grinding applications.

8. Staggered segments diamond grinding discs are designed to be compatible with various grinding machines, including angle grinders, floor grinders, and handheld grinders. They come in different sizes and arbor configurations to suit different equipment models.

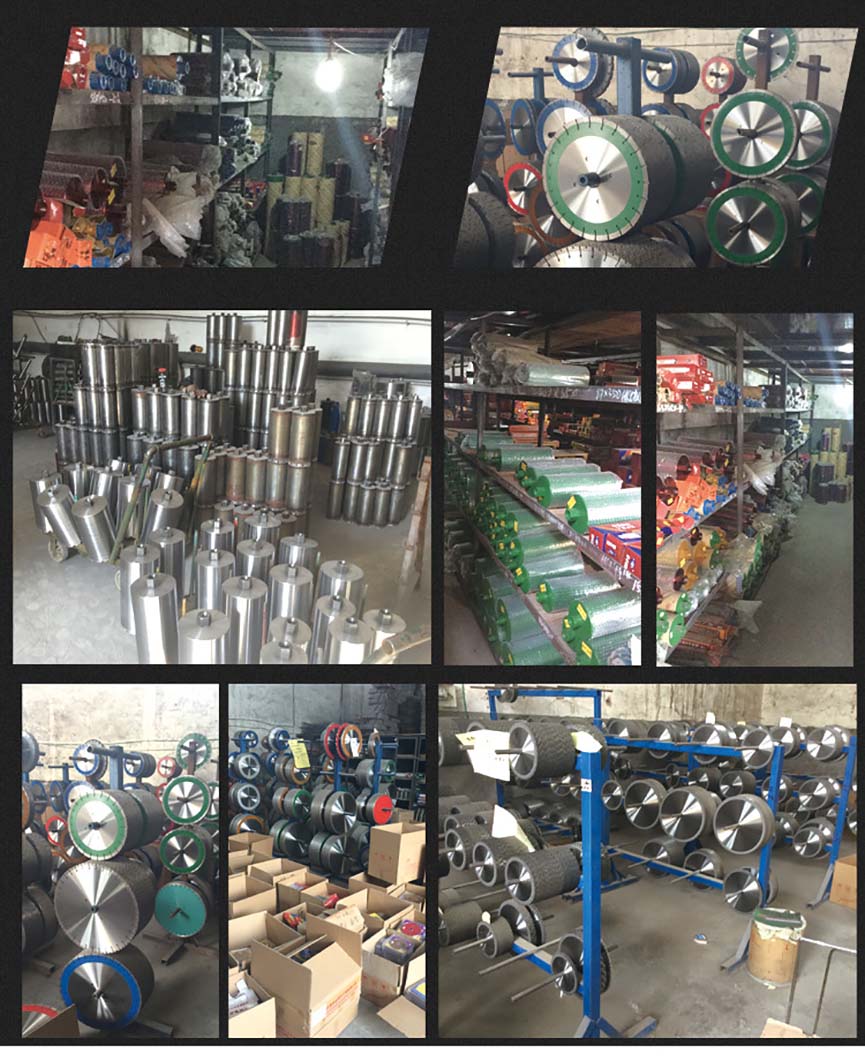

Workshop

package