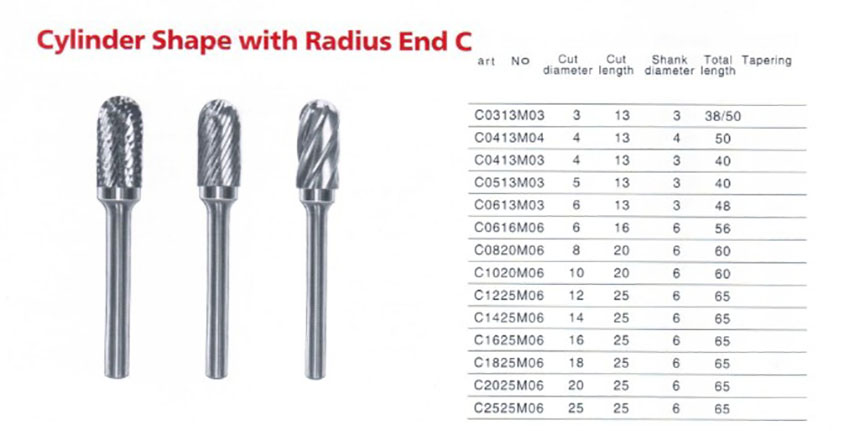

Tungsten Carbide C type Ball nose Rotary Burrs

Advantages

PRODUCT SHOW

1. Reduced Chipping and Breakage: The ball nose design reduces the risk of chipping or breaking the material being worked on, especially in delicate areas or when working with brittle materials. This helps to prevent damage and ensures a higher level of accuracy.

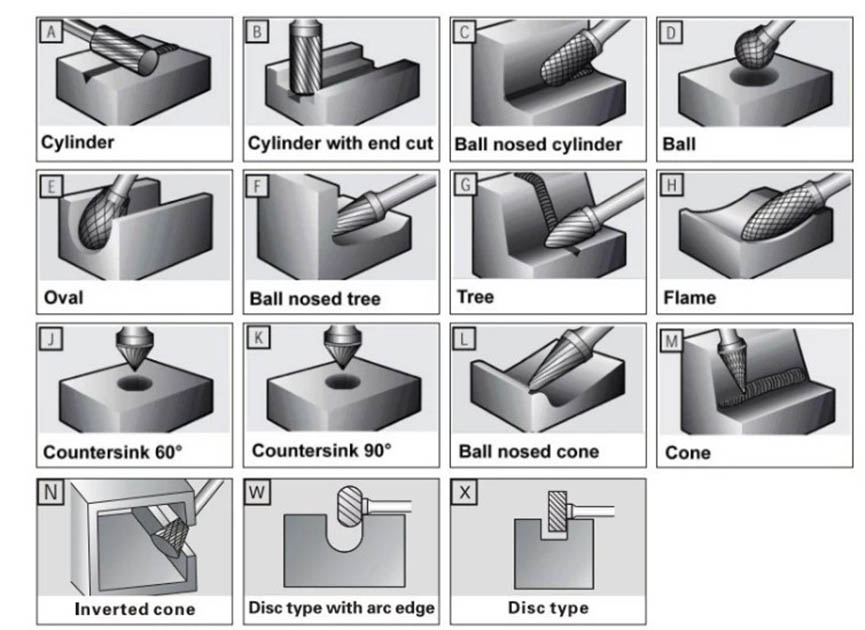

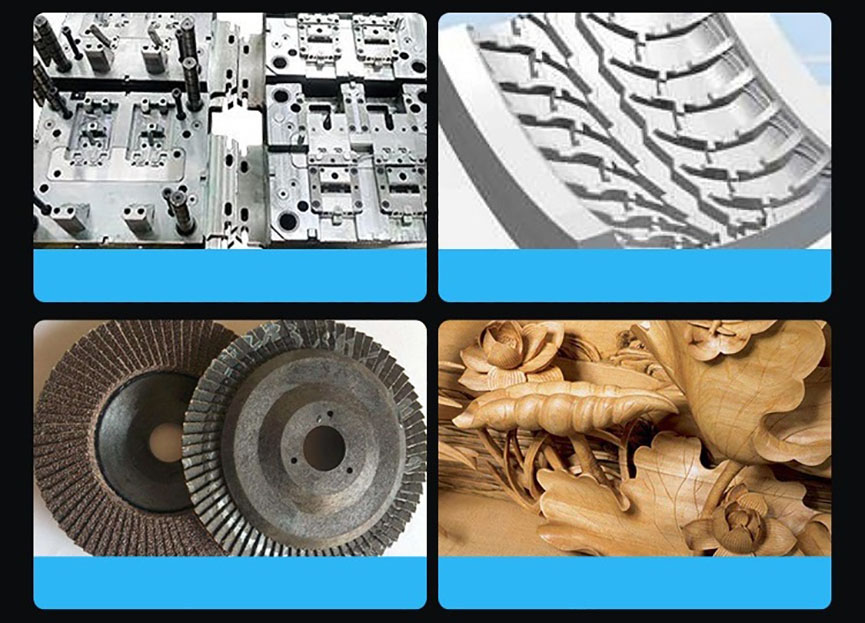

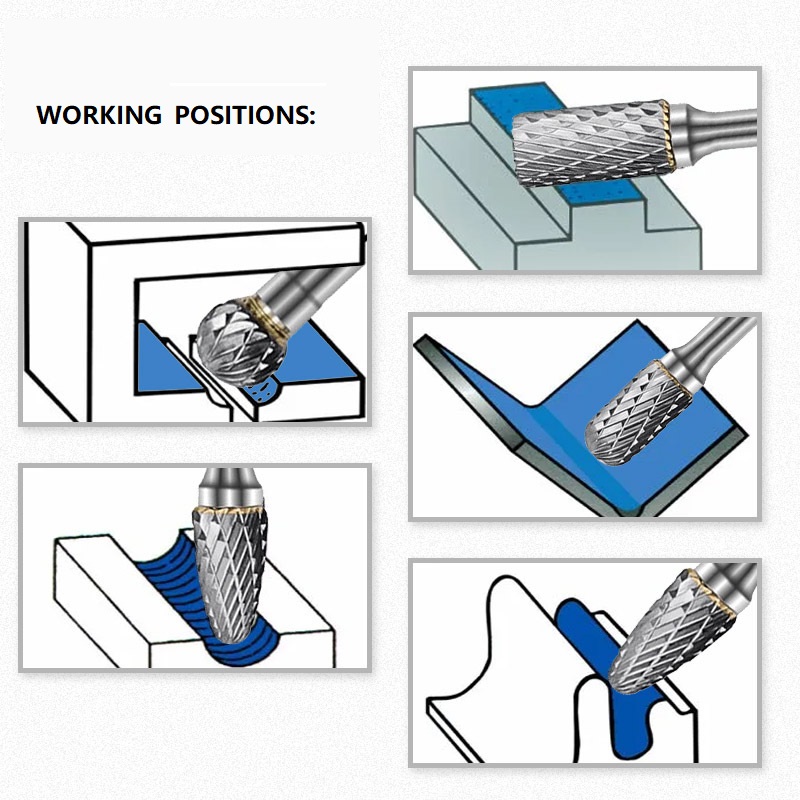

2. Versatility and Flexibility: C type ball nose burrs can be used on various materials, including metals, plastics, wood, and composites. They are ideal for tasks such as blending, shaping, and smoothing, making them versatile for different applications and industries.

3. Efficient Stock Removal: While primarily used for finishing work, C type ball nose burrs can also efficiently remove stock material when needed. Their rounded profile allows for controlled material removal and contouring in tight spaces or difficult-to-reach areas.

4. Long-Lasting Performance: Tungsten carbide C type ball nose burrs are highly durable and can withstand high-speed rotary tool operations. They maintain their sharpness and cutting effectiveness over an extended period, reducing the need for frequent replacements and improving productivity.

5. Heat Resistance: Tungsten carbide is known for its high heat resistance. C type ball nose burrs can withstand the heat generated during cutting, preventing overheating and maintaining their performance and longevity.

6. Compatibility: C type ball nose burrs are designed to be used with high-speed rotary tools such as die grinders or electric drills. They are compatible with various tool manufacturers' devices, making them easily accessible and widely used.